We’ve all used keyboards as long as we’ve been using computers. However very few of us know about all the different types of keyboards out there. Most of us have used normal or membrane keyboards as they’ve long been the most popular type of keyboard.

This is due to them being the cheapest and simplest to produce. The second most popular keyboard type is a mechanical keyboard which has increased in popularity in the recent years.

Interestingly the first keyboard ever made by IBM was actually a mechanical keyboard. Aside from these two popular keyboard types, there are tons of different keyboard types for many different purposes.

We explain below what they are and what their different use cases are. First let’s start off by explaining what the differences between a mechanical keyboard and a membrane keyboard are.

Membrane Keyboards

Membrane keyboard have fast become one of the most popular types of keyboards. This is mostly due to their cheap manufacturing costs and silent operation.

There are in fact two different types of membrane keyboards as well. One of them is flat-panel and the other one is a full-travel membrane keyboard.

Flat-Panel Membrane Keyboard

Flat-panel membrane keyboards are usually located on home devices like microwave keypads or flat remote controllers.

Smaller devices like audio systems utilize these types of controllers. A usual flat-panel membrane keyboard consists of multiple layers stacked on top of each other.

Top Layer

The top layer consists of soft plastic to allow for some push back and haptic feedback.

This makes it easy for the user to recognize when a button has been successfully pushed down.

This works similar to the click on a mechanical keyboard. It has all the controls and characters printed on the topside of it.

It has conductive material on the other side of the plastic under each key. That conductive material makes contact wit the next layer and tells the system which button actuated.

Spacer Layer

Next, under the top layer is a spacer layer. The spacer layer separates the top and bottom layers apart from each.

The construction prevents the conductive materials from touching each other when buttons are in the idle state.

Bottom Layer

The last or bottom layer also has conductive strips on it printed opposite to the ones from the top layer. They are perpendicular from the top layers conductive material. This way they form a conductive grid when actuated.

When the button travels down, the top layer moves down through the spacer. This forms contact between the two circuits on the top and bottom layers. This way the computer or the control block knows which key actuated, communicating this to the device.

This keyboard structure is extremely simple and cheap to build. That is why it’s used in so many small and simple devices as they usually need only a few functions.

They’re also great for harsher environments where things like waterproofing is necessary. The solid plastic cover prevents any water from seeping through the buttons or keys unlike other keyboard types.

Full-Travel Membrane Keyboard

Full-travel membrane keyboards are the types of keyboards that almost all computers come with as a stock option.

Their buttons consist of separate plastic molds, more commonly known as keycaps. They make contact with the membrane layer. Springs are under they keycaps pushing contact down on the membrane.

Once the spring touches the contact point on the membrane layer, it tells the PCB which button is actuated.

This type of keyboard doesn’t provide much haptic feedback when a key actuates and it makes little to no sound. Due to this, full-travel membrane keyboards are more popular in comparison to flat-panel membrane keyboards especially in office situations.

They can usually be seen on laptops and by users who do more typing or sit in an office building. This applies to environments where noise can be an issue.

Membrane keyboards do have other limitations as well when compared to mechanical keyboards. We explain the differences later in the article at the mechanical keyboard section.

Dome Switch Keyboard

Dome-switch keyboards are also know as Chiclet keyboards and direct-switch keyboards. They are fairly unique on their own and not among the most popular types of keyboards.

They combine the technologies of flat-panel membrane keyboards alongside some features of mechanical keyboards.

A dome switch keyboard connects two circuit boards under a silicone pad using metallic dome shaped switches. These types of switches are more firm and provide the user with a better haptic and tactile feedback.

Metallic switches are the most popular for dome switch keyboards. They can consist of any extremely durable material like gold to provide for a very long lifespan.

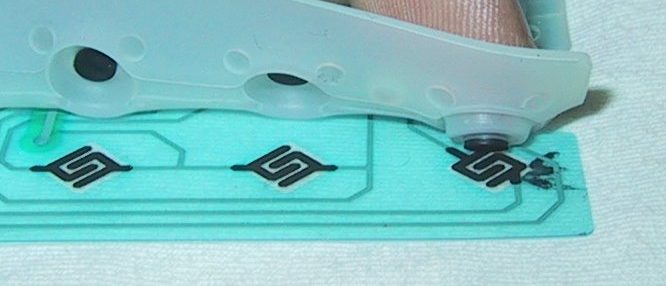

The dome switches are also often made out of plastic, which is the cheaper alternative. These plastic dome switches have a tiny piece of graphite at the pit of the dome that provides the contact point.

As they are cheaper and easier to build, they’re also less durable in comparison to the metallic domes. That is why they might not always be the optimal choice.

They are also more quiet, but provide less tactile feedback when pushed down. This splits opinions quite often but they both have their own use cases.

For either key type, a dome switch collapses when it moves down. This in turn connects the two circuits and attaches the connect points to each other.

This way the PCB or printed circuit board knows which button actuated. Both metallic and plastic dome switches are a regular occurrence in the consumer keyboards today.

Aside from keyboards, dome switch technology is popular in console controllers, mobile devices, cars and all kinds of home electronics.

Scissor Switch Keyboard

The scissor switch type of keyboard is a newer type of keyboard that incorporated the dome technology as well.

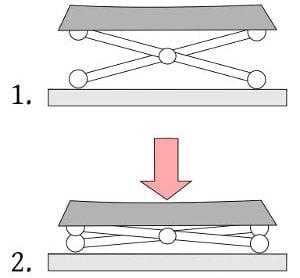

The scissor switch is a specific type of keyboard key that attaches via two separate layers in a scissor formation.

The key uses a special combination of metallic structures making contact with the bottom of the keycap and membrane layer.

The scissor switch uses the usual plastic dome to activate, but the plastic is in a special scissors-type mechanism.

This is links the keycap to a plunger. The plunger contracts the actual dome in a much shorter distance. This applies when compared to the usual plastic dome keyboard key.

Scissor switch keyboards often consist of three different layers. This combines the pressed key and the printed circuit board.

The main attraction of a scissor switch keyboard is the lower travel distance. The difference is 2 millimeters instead of 3–4 millimeters of a normal dome-switch key.

This is one of the more usual key types on new computer and laptop keyboards. These are low-profile or low travel keyboards. Scissor switch keyboards are quiet and have fast travelling keys as they require less force by the user to actuate.

Scissor switch keyboards are usually more expensive than other membrane keyboards. This is mostly due to the more difficult requirements for construction.

Scissor switches are also more compact than other key types. This means they’re harder to clean and have less space between the layers, but gather less dirt to begin with.

Some modern keyboard manufacturers advertise scissor switch gaming keyboards to appeal to the streaming audience. This is because they make very little noise while taking advantage of the ghosting capabilities of a mechanical keyboard.

Capacitive Keyboard

Capacitive keyboards are electrostatic keyboards. They work by using the contact on capacitor pads and monitoring the change between them.

The keys contain insulating patterns made of specific materials on both the key and the printed circuit board layer. This allows the identification of contact.

Unlike other types of keyboards, in capacitive keyboards electricity flows constantly storing charge in capacitors. In other keyboards electricity flows only when a key actuates.

How an Electrostatic Keyboard works

In technical terms a capacitive keyboard sounds complex when compared to other keyboards but in theory they are fairly simple. The bottom of the keycap contains a small aluminum piece.

It is the point of contact between the PCB and the key itself. Opposite the key switch is the PCB containing the actual capacitor pads.

When the user presses a key down, it forms contact with the surface of the PCB. This creates a daisy chain of the two separate capacitors between the two contact points.

The contact points separate using a thin solder mask. This causes a short between the contact pads because of a drop of capacitive reactance between the two pads.

Generally this causes a pulse for the PCB to recognize and send forward. The switch itself doesn’t have actual electric contact, so there isn’t any debouncing happening between the points.

What are the Benefits of a Capacitive Keyboard?

The main benefit of capacitive keyboards are that the keys don’t need to make contact with the PCB for the electric contact to register. This is due to its conductivity. This allows for the user to type with shorter key presses and less force.

The sensors within the PCB tell the computer enough information about the key position.

This allows the user to adjust the actuation point of the key press. This actuation is also modifiable using separate software by the user.

This way they can make the key presses travel distance optimal for each use case.

Mechanical Switch Keyboard

On a mechanical switch keyboard, each key consist of a separate keycap and a key switch under the keycap. Each key switch contain a housing for the components, a spring for push-back, and a base called a stem.

Some keys might also contain a click bar for more advanced haptic feedback. Some also have a contact leaf for improved key press recognition.

Mechanical switch keyboards are the among the most popular types of keyboards alongside normal membrane keyboards. Mechanical switches usually fall into one of three different key categories.

Three categories of mechanical switches

They can be linear which have consistent resistance to the touch.

A second type of key is a tactile key, which has a silent push, instead of a clicking noise.

The last type of key is clicky, the most popular key with tactile feedback and an iconic clicking sound.

The springs inside the switches determine how much force one needs to push down each key. You should take not of this when choosing the type of switches for you.

Why are mechanical switch keyboards so popular?

The switches are manufactured in tons of different shapes and sizes depending on the wanted actuation distance is.

The length of the actual travel distance also affects the manufacturing design. Due to the noise that mechanical keys make, it is also possible to add dampeners to lower the sound.

Dampeners consist of a special soft rubber. The use of dampeners often depends on where the user needs to use the keyboard. An office environment or a private room often require different noise levels.

Due to the stem shapes, mechanical keyboards allow for very easy keycap removal. That is one of the key features why they are so popular. They’re very easy to customize and make them look your own.

Compared to normal membrane or dome-switch keys, mechanical keyboard keys generally have a much longer lifespan. It generally ranges between 50-60 million key presses.

This is an extremely high durability in comparison to a normal membrane keyboard. Membrane switches normally sport approximately 5 million key presses per key.

Buckling Spring Keyboard

A buckling spring keyboard is a special keyboard that uses a unique type of switch mechanism. This mechanism originated from IBM, who also held multiple patents for the mechanism back in the day, all of which have now expired.

The unique name of this key switch refers to it’s function.

Hence the key contains a coil spring that tenses between the keycap and hammer buckles.

These buckles pivot when the spring moves downwards. The spring bends to the side and moves the hammer in a specific direction.

Once the spring bends and the hammer buckles, it pivots forward from the contact point of the the spring.

This causes an electrical contact point which in turn registers the press of the key.

The electrical contact initiates from a layer similar to the ones used in membrane or capacitive keyboards. They act as the middle ground for the electrical contact.

The buckling spring mechanism is the preferred keyboard type for many typists even today.

Hall Effect Keyboard

Hall effect keyboards take advantage of small magnets in each key and their contact points. The keyboard uses sensors instead of normal switches that would have mechanical contact points.

Once a key moves downwards, the magnets move towards each other. A special solid-state sensor then detects this positional change.

As the keys don’t actually to make contact with each other, this makes Hall-effect keyboards extremely durable and reliable.

This also allows them to have a life span of hundreds of millions of key presses before breaking or failing. When it comes to different types of keyboards, they’re not very common and not known about by consumers.

Normal day to day keyboards for average users don’t usually contain Hall Effect switches. In fact the Hall Effect keyboard technology is mostly used in ultra-high reliability scenarios and applications.

These include crucial operation of nuclear power plants or aircraft operations. They can also be easily manufactured to be completely water and dust-proof alongside any other contaminants.

Each key requires two magnets, a special sensor alongside custom control electronics. This makes them extremely expensive to manufacture.

Optical Keyboard Technology

Optical Keyboard Technology goes by various different terms and names. They include photo-optical keyboards, photo-electric keyboards, light responsive keyboards, and optical key actuation detection keyboards.

How an optical keyboard works

Optical keyboard technology makes use of light-emitting parts and special photo sensory technology to optically detect the pressed keys.

These sensors and emitters mount on the printed circuit board of the keyboard. The actuated keys block the emitting light coming from the emitters.

Most optical keyboards take advantage of two separate beams, one in a vertical and the other in a horizontal fashion. The PCB then determines which key actuates using the two light beams.

There are specific optical keyboards that only utilize horizontal beams. They consist of one beam for each row of keys. Each beam then detects which key from that row actuates at one time.

This however limits the amount of keystrokes that can register at one time. Most older optical keyboards only supported the pushing of one key at a time. This was due to the limited option of a rectangular casing for the keyboard. This limited the blocking of the light beams to actuate a specific key.

What are the benefits of an optical keyboard

The main benefit of using an optical keyboard is that it requires a lot less space. Optical keyboards sizes are often about twenty percent smaller.

This way the printed circuit board size is also smaller in comparison to other membrane keyboards.

It also allows for easier waterproofing. This causes less electrical waste and simpler manufacturing for many parts of the keyboard. This way the costs stay moderately low compared to most of the other keyboard types.